The cooking oil solution for locations with unique floor plans and large footprints.

Your kitchen moves fast. Your oil needs to keep up. The days of your staff slowly (and dangerously) shuttling hot oil all the way from the kitchen to the loading dock and dumpster are over. Our portable oil solution keeps your kitchen running (safely) at the pace you want.

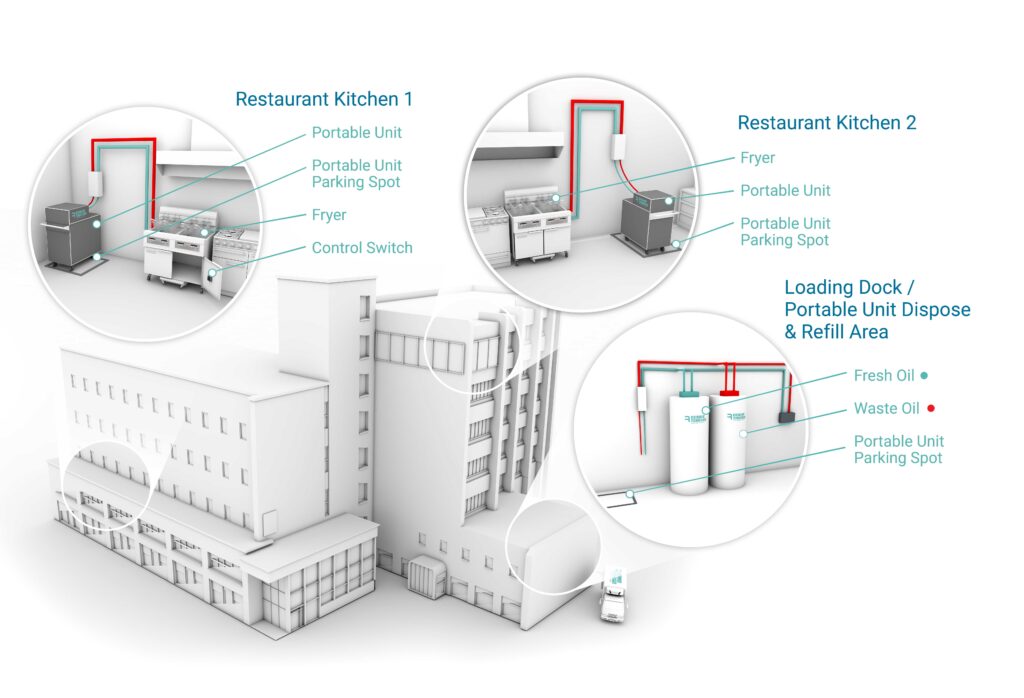

Unique Site Requirements? No Problem.

For many food service establishments, there are significant distances between the fryer and

disposal area, or even kitchens on multiple levels. Your staff shouldn’t have to shuttle oil back

and forth using unsafe methods. Our portable solution keeps your employees safe and gives

you the tools to make outstanding food, every time.

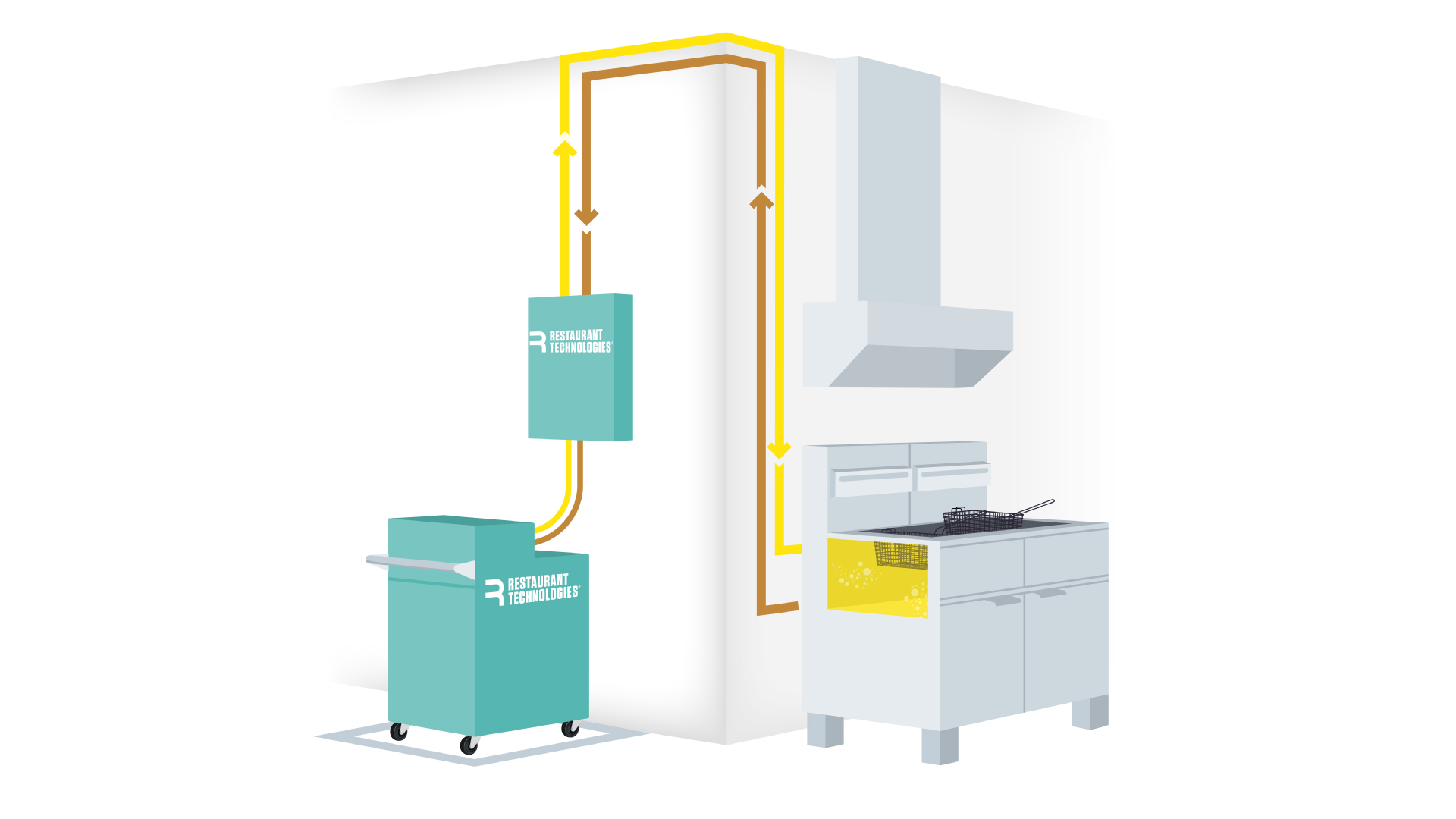

How It Works

This is the cleanest, safest way to contain and transport oil in your multi-level, multi-kitchen

facility. We provide a portable unit that can be parked near the kitchen with lines running

directly to your fryers or moved into the kitchen to service fryers directly. Employees can add

fresh oil and pump out used cooking oil at a fill station located at the loading dock connected to

the stationary bulk oil tanks without ever handling hot oil.

Save on Your Insurance Premiums.

Automate your cooking oil management to improve safety, efficiency, and food quality.

The Smart Solution

- Eliminate loading, storing, and retrieving 35 lb. jugs

- Eliminate labor-intensive oil handling or long transfers across property

- Prevent wasted or spilled oil

- Eliminate employee exposure to hot oil

- Reduce slips, falls, burns and associated workers’ comp claims

- Encourage more diligent filtering

- Improve back-of-house security

- Eliminate cardboard and plastic waste associated with oil containers

- Receive competitive used cooking oil compensation

- Improve food quality consistency

The Custom Solution for Your Property

- Restaurant Technologies provides a fresh oil tank and a waste oil tank at a loading dock or accessible delivery location

- Portable unit connects to the fresh oil and waste oil tank to dispose and refill

- Portable unit is parked near the kitchen with lines running directly to the fryer or moved into the kitchen to service fryers directly

- Enclosed unit ensures employees never have to touch a drop

- Fresh oil is delivered, and waste oil is picked up via a lockable outdoor fill box

- Onsite coaching, training, account management, and 24/7 service provided

- Customer web portal provides up-to-the-minute usage reports, tips, and alerts

- Everything is handled for you with no disruption to your business