Oil management has long been a struggle for restaurants and commercial kitchens. If you get jugs of fresh oil delivered on one truck and get grease removal and recycling from old-fashioned “guy with a truck” renderers, it’s about time you upgrade your management practices regarding cooking oil for restaurants.

To better understand your current processes (and what you can do to improve), the oil experts here at Restaurant Technologies created this Oil Management 101 page, dedicated to covering every aspect of cooking oil management.

Getting the best returns on oil investment and fried food costs is critical to sustaining your foodservice business. While most organizations have some form of procedure to track basic oil spend and handling costs, there’s still lots of room for error.

A series of disconnected steps — including oil purchase, delivery, grease disposal, and recycling — obscures important insight into key oil metrics. These metrics include oil usage over time, across locations, or within certain operating parameters. Without these metrics, businesses are vulnerable to gaps in efficiencies and missed training opportunities, ultimately a loss of time and money.

In addition, there are the overlooked safety expenses. These costs can add up to thousands of dollars per location per year. Just look at the numbers:

Cooking oil management can be broken down into four key stages:

In the U.S., the most popular vegetable oil is soybean oil, with an impressive 70% of the market share. It’s followed up by canola, corn and palm oils.

Whatever oil variety you use, the cost will vary over time due to changes in supply and demand. So, while cost is an important factor to consider, your decision should also factor in taste, smoke point, and health considerations, including cooking oil allergies and the effects of certain oils on the heart.

In addition, be wary of changing your oil due to temporary price fluctuations. Switching will alter the flavor of your product, potentially alienating customers. And mixing oils is especially ill-advised — differences in smoke points can increase the risk of oil fires.

Buying cooking oil in bulk not only saves money, it can be an exceptional strategy for streamlining your oil delivery and utilization processes.

While every type of oil has a different price point, you will pretty much always save when buying in bulk.

When signing a contract with an oil delivery service provider, ask about the cost difference if you choose the bulk cooking oil option. It’s also a good idea to inquire if your service provider is capable of handling the recycling process as part of a closed-loop system.

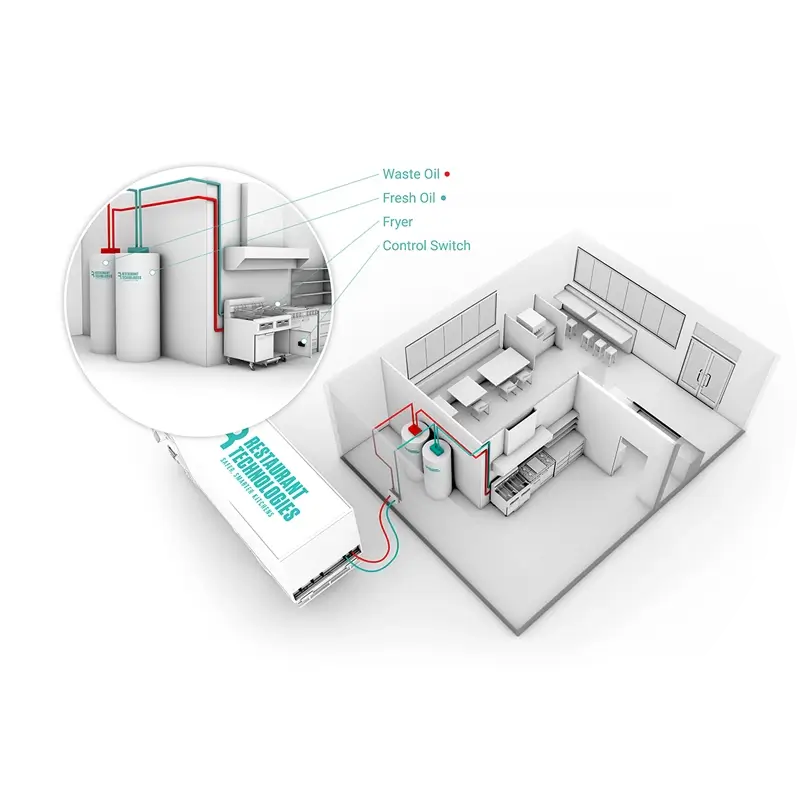

How you receive your oil delivery can also be a source of savings. When it’s delivered in bulk to a single, central tank, like it is with Restaurant Technologies’ Total Oil Management, and automatically sent to the fryer, you completely eliminate the time spent on handling by your staff.

How Often Should You Have Oil Delivered?

To avoid running out of oil, you should have new fryer oil delivered when you are down to between 3 and 5 days of oil inventory remaining. For kitchens that are using Restaurant Technologies’ Total Oil Management system, this averages to 1 delivery every 4 to 5 weeks.

However, if anything delays or accelerates your typical delivery schedule, the Total Oil Management tanks are connected to the cloud. This ensures accurate volume information is always communicated to the delivery team, and you’re never left dealing with too much or too little.

Receiving and Storing Oil Deliveries

If you have your cooking oil delivered in jugs or drums, you need to ensure you have sufficient storage space available in a cool, dry location. On the day of delivery, you’ll need to also ensure you have sufficient staff on hand to monitor and potentially assist with unloading.

The other delivery option is bulk delivery of commercial fryer oil directly into an oil storage tank through an external port. This method of delivery is generally easier, faster and more efficient. These deliveries can be made without taking up employee time or extra storage space.

Further advantages come when your tank has automatic volume sensors. Such sensors allow managers to remotely monitor deliveries and existing oil levels.

Never leave jugs of oil on the floor. This can result in pooling oil and significant slipping hazards. Store them on a pallet or another elevated surface, out of the way of the general flow of traffic.

As oil is being used, it should be continually monitored and consistently filtered. Filtering maintains optimal color and taste for longer. It also extends the overall life of the oil by removing food debris, which causes the oil to degrade over time. In short, regular filtration saves you money and improves your fried food product.

There are two main choices when it comes to filtering your cooking oil — manual filtration and fryer filter machines.

Manual filtration can be used when an electric fryer oil filtering machine isn’t available. The oil is allowed to cool to between 250 and 300 degrees Fahrenheit. It’s then removed from the deep fryer and poured through a filter into a receiving pot. The deep fryer can then be cleaned of any debris and the filtered oil re-added.

This process comes with significant safety risks, as it exposes employees to potential oil burns and slipping hazards.

Fryer filter machines allow for electric filtration, as opposed to manual. These systems can be built-in to a fryer cabinet, or they can be portable. The easiest solutions are built-in and hands free, allowing the operator to filter the oil with a few simple commands.

The average commercial kitchen using a fryer filter machine should be filtering at least once a day for 5 minutes per vat. However, high-volume operations or kitchens with smaller frying vats will benefit from filtering more frequently.

There are multiple steps to proper disposal of frying oil. These steps are designed to minimize the amount of oil and grease that ends up in the sink.

Accumulations of oil and grease can form rock-like masses in our sewers, colloquially known as ‘fatbergs,’ that are extremely difficult and expensive to remove. For this reason, some municipalities have made it illegal to dump grease down the drain without proper systems in place.

Traditionally, after it was done being used for frying, cooking oil and grease were drained into caddies or buckets, removed from the kitchen by staff, and allowed to cool. Once cool, the oil and grease can then be bagged and discarded in the trash.

While this is an effective way to keep excessive grease from going down the drain, it’s also dirty work with a high risk of slips, strains and burns. Nowadays, the shuttling process is becoming outdated. Across the industry, commercial kitchens have come to realize that some of the most dramatic process improvements they can make are in oil management.

In recent years, commercial kitchens have recognized the need for more efficient, safer, and environmentally friendly cooking oil disposal methods. The best choice for cooking oil removal is automatic and touchless. Restaurant Technologies’ Total Oil Management system allows for easy, hands-free recycling of frying oil. This means enhanced safety, efficiency, food quality and sustainability.

Best Practices for Recycling Cooking Oil and Grease

When collecting your used cooking oil and grease prior to recycling, it’s important to remember this is a valuable resource that needs protecting. Thievery of used cooking oil has been on the rise. Storing your yellow grease in an un-secured container leaves you vulnerable.

Another key factor to remember? Contaminants. Regular filtering during the life of your fryer oil is an important first step, but contamination can become a problem during storage as well. Once again, a secure container kept in stable environmental conditions is the optimal solution.

Once collected, yellow grease from commercial kitchens is filtered to create ‘feedstock’ oil. The feedstock is then treated with methanol and a catalyst, producing glycerin as a byproduct. The glycerin is used in many different applications, from cosmetics to toothpaste.

Finally the excess methanol is processed out, leaving pure biofuel behind. Biofuel can be mixed in with conventional diesel to create a more sustainable, eco-friendly fuel. The biofuel has a low carbon content, and it doesn’t produce carbon monoxide.

Used cooking oil is already playing a part in powering airplanes, shipping goods cross-country, and heating homes, while reducing the environmental impact of all those activities.

Restaurant Technologies, Inc.

2250 Pilot Knob Road

Mendota Heights, MN 55120